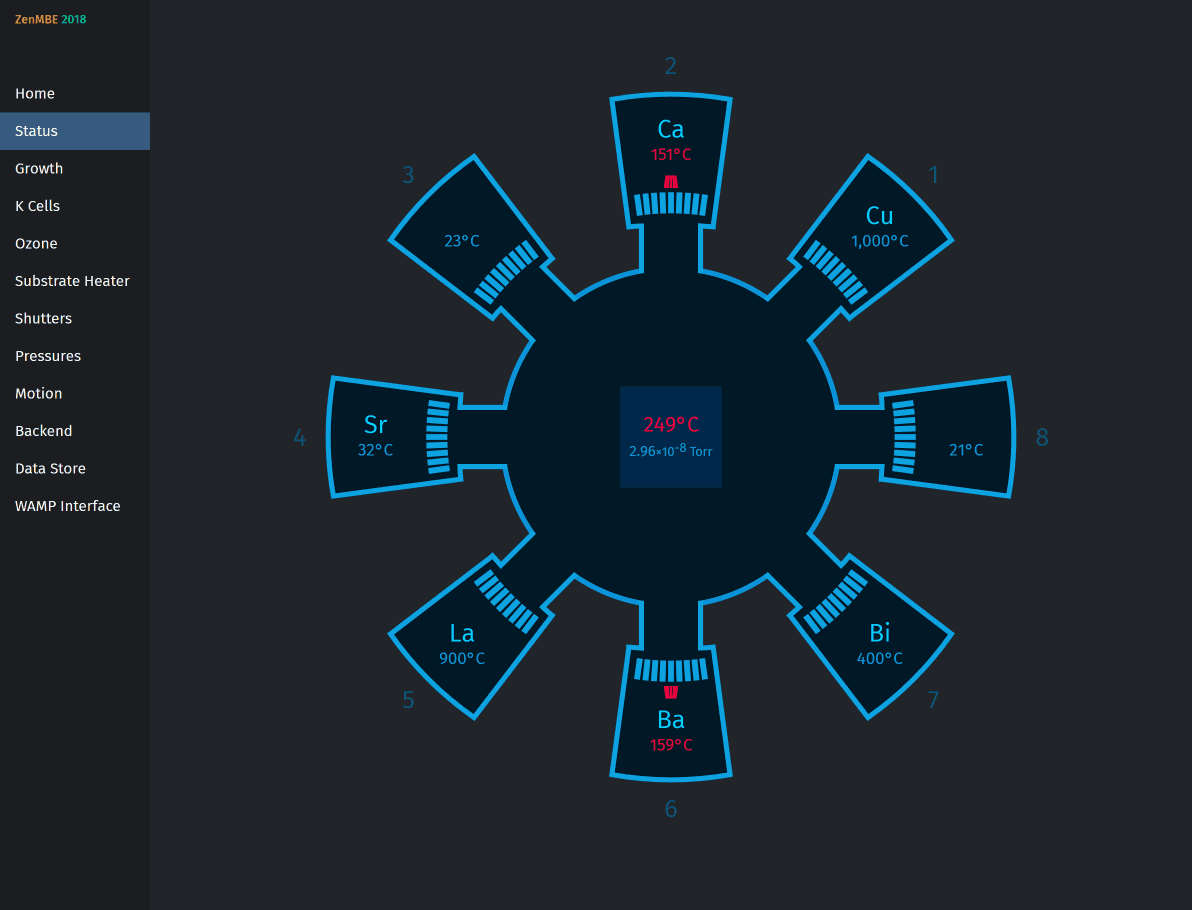

The ZenMBE System

If you need the maximum amount of precision possible from your molecular beam epitaxy (MBE) system, look no further than ZenMBE. By precisely controlling your entire MBE system through advanced data analysis techniques in real-time—including precise control of oxygen sources in oxide molecular beam epitaxy (OMBE) systems—you can be sure that your system reaches its full potential.

The ZenMBE line of software and hardware has been used for real-time control of molecular beam epitaxy systems since 1999 in laboratories around the world.

The ZenMBE Way

ZenMBE is based on “the Unix philosophy.” In The Bell System Technical Journal from 1978, Doug McIlroy explained the Unix philosophy as follows:

- Make each program do one thing well. To do a new job, build afresh rather than complicate old programs by adding new “features.”

- Expect the output of every program to become the input to another, as yet unknown, program. Don't clutter output with extraneous information. Avoid stringently columnar or binary input formats. Don't insist on interactive input.

- Design and build software, even operating systems, to be tried early, ideally within weeks. Don't hesitate to throw away the clumsy parts and rebuild them.

- Use tools in preference to unskilled help to lighten a programming task, even if you have to detour to build the tools and expect to throw some of them out after you've finished using them.

Simplified, the Unix philosophy is as follows:

- Do One Thing Well: Each program focuses on a single task.

- Interoperability: Design programs to work together.

- Iterative Development: Try and revise software early and often.

- Tool Over Manpower: Use automated tools instead of manual labor.

To this end, ZenMBE is simple, flexible, and reliable:

- Simple

- The ZenMBE system is comprised of dozens of small, independent components, each performing a specific task in a focused and well-defined way.

- Flexible

- The components of the ZenMBE system are designed to easily work together, so that complex tasks are accomplished by “plugging together” the components, without having to reinvent wheels for each new task.

- Reliable

- The ZenMBE system is purposefully designed to run unattended day-in, day-out for years on end without fail, so its components are stable and perform without side-effects.

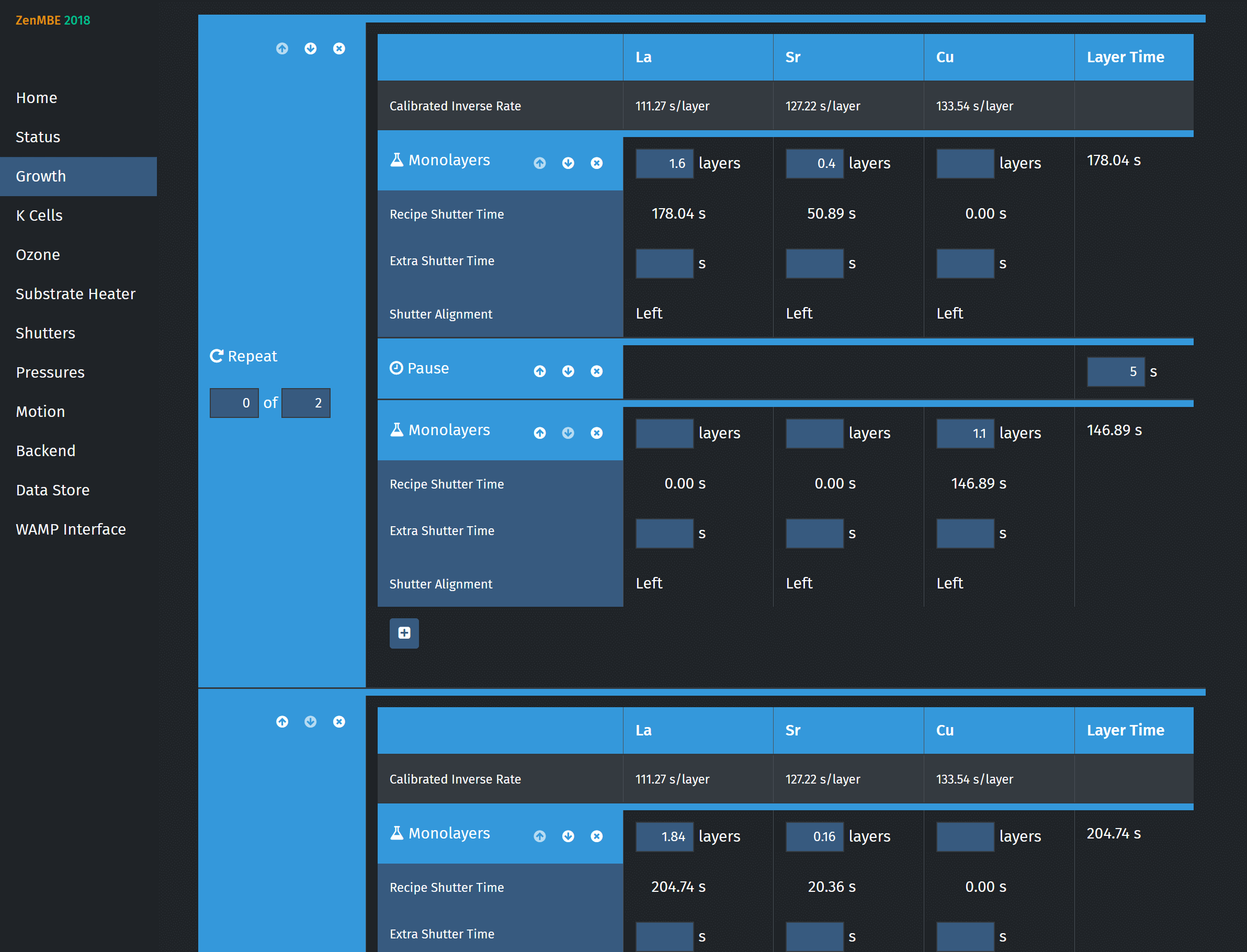

Recipe Editor

The ZenMBE recipe editor makes designing and growing your materials simple and straightforward.

ZenMBE Components

The ZenMBE suite consists of two subsystems:

- ZenMBE—The user interface and front-end for real-time interaction with your MBE system. Can be run on any computer, anywhere in the world that has connectivity to your lab network (either directly or via a VPN).

- sZenMBE—The back-end interface that synchronizes all of the MBE operations and communicates between the front-end and the hardware abstraction layer

Additionally, there are a large number of plugins and extensions which can be installed to interface with particular pieces of hardware and perform various tasks, and various hardware modules to serve as bridges to equipment.

ZenMBE utilizes the zents high-performance real-time time-series database to record every single sensor reading for all of time.

Using optional integration modules, ZenMBE can directly control D. J. Bernstein’s daemontools as well as Docker. This allows individual components to be enabled and disabled remotely as needed for maintenance and upgrades. Each component can be kept compartmentalized, as either a daemontools service or a Docker container. Containers and services can be mixed and matched across individual or multiple machines.

ZenMBE Hardware Support

ZenMBE is regularly updated and maintained. As of 2025, the current version supports and directly interfaces with over two hundred different pieces of hardware from various manufacturers. Additionally, the system is fully modular and support for new hardware is generally trivial and inexpensive to add.

Even for devices not currently integrated into a system, ZenMBE provides the ability to connect additional hardware interface modules, and Zensoft provides custom hardware interfaces when necessary. We can support interfaces and protocols ranging from Ethernet, RS-485, and SCPI to proprietary bidirectional one-wire interfaces.

Some of the over 200 pieces of hardware that ZenMBE directly supports includes:

- Agilent XSG-600 gauge controllers

- Delta Elektronika ES-150 series (ES 030-5) power supplies

- Eurotherm 2408 modules

- Eurotherm 3504 modules

- Granville Phillips GP 350 and GP 370 Stabil-Ion Bayard-Alpert vacuum gauges

- Hewlett Packard HP 34401A digital multimeters

- Inficon QCMs

- InstruTech CM201 Super Bee Pressure Gauges

- IS 50-LO Plus pyrometers

- Keysight 34460A, 34461A, and 34465A digital multimeters

- Omega DP1001AM scanners

- RHT003 hygro-thermometers

- PF900 power supplies

- Pfeiffer DPG-202 units

- Productivity1000, Productivity2000, and Productivity3000 PLCs

- PSC-488 modules

- Veeco 1508 power supplies

- Zensoft MCR-1610 stepper motor controllers